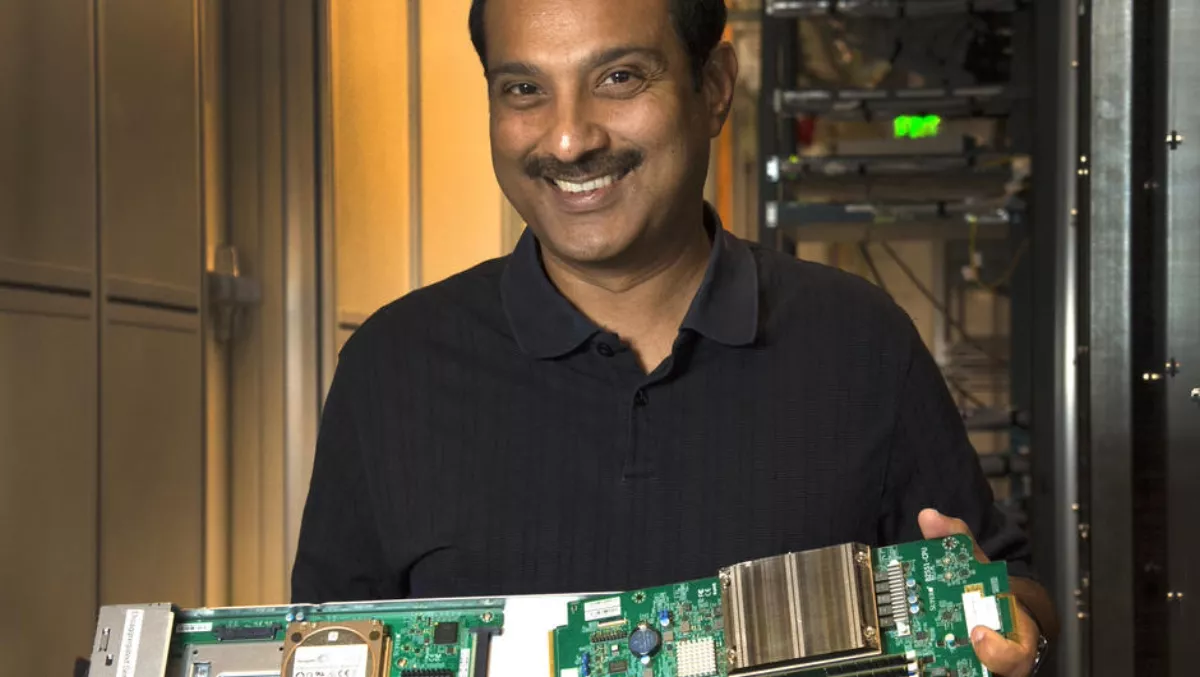

Intel Fellow and IT chief technical officer Shesha Krishnapura found a way to save money and reduce waste by creating a modular server design that allows critical components to be upgraded easily.

How he'd describe his job to a 10-year-old“My job at Intel is to build massive labs called data centers, which hold more than 200,000 interconnected computers, to aid more than 50,000 engineers to design and develop not only the world's most powerful computer chips, but also software tools that help build smart and connected devices.

The light-bulb momentStaying on top of Intel's insatiable, growing (up to 40% a year) demand for data center power and high-performance tools while carefully minding costs is the challenge Shesha and his team face.

They've responded by building one of the most energy-efficient data centers on the planet in the shell of an old Santa Clara microprocessor factory.

It is cooled only by fans, passive radiators and recirculating grey water — with space for future growth.

But frequent server upgrades had an unfortunate side effect, as Shesha saw it: “All these perfectly good power supplies, fans, cables, chassis and drives are sent to recycling. It's really painful.

Though hardware design is not a typical service offered by an IT shop, Shesha had an idea: make upgrading a server more like replacing a light bulb.

Cutting the bladeThe industry-common “blade” server design helps reduce some of that upgrade waste, allowing the processor, memory and storage to be replaced independently from longer-life components.

Shesha wanted to take that modularity another big step: split the motherboard in two and separate the processor and memory from the much slower-evolving input-output parts.

He whiteboarded the design, earned support among Intel technical leaders and connected with a manufacturer.

From the first meeting to actually installing the first machines in the data center took a mere 5 weeks — and the reorganised motherboard added only $8 to the cost.

Trading 8 bucks for big-time savingsAs a result of all this, Shesha estimates that a $10 million server upgrade would now cost only $5.6 million — 44% less — and save 77% in technician time versus a full “rip and replace” upgrade.

In Santa Clara, some 70,000 of these new machines now fill an entire towering row.

The “disaggregated server,” as he calls it, allows data center managers like himself “to invest in emerging technology without wasting money on replacing technology that is not evolving.

‘I'm extremely frugal'Shesha isn't coy about what inspired him to take this path.

“I'm extremely frugal,” he confirms with a laugh.

“In my personal life, I have always used things for their full useful life, and extend, where possible, with minimal maintenance, whether it is household appliances or automobiles.

“Then the question came to my mind: how to extend selectively what we invest in data center IT equipment in a way that is both financially rewarding and environmentally responsible?

“That was the motivation for disaggregated server design.

Frugality pays off in many ways — Shesha's project team earned the Intel Achievement Award, the company's highest honor, for bringing the disaggregated server to life.