Formlabs unveils Form 4 range, revolutionising professional 3D printing

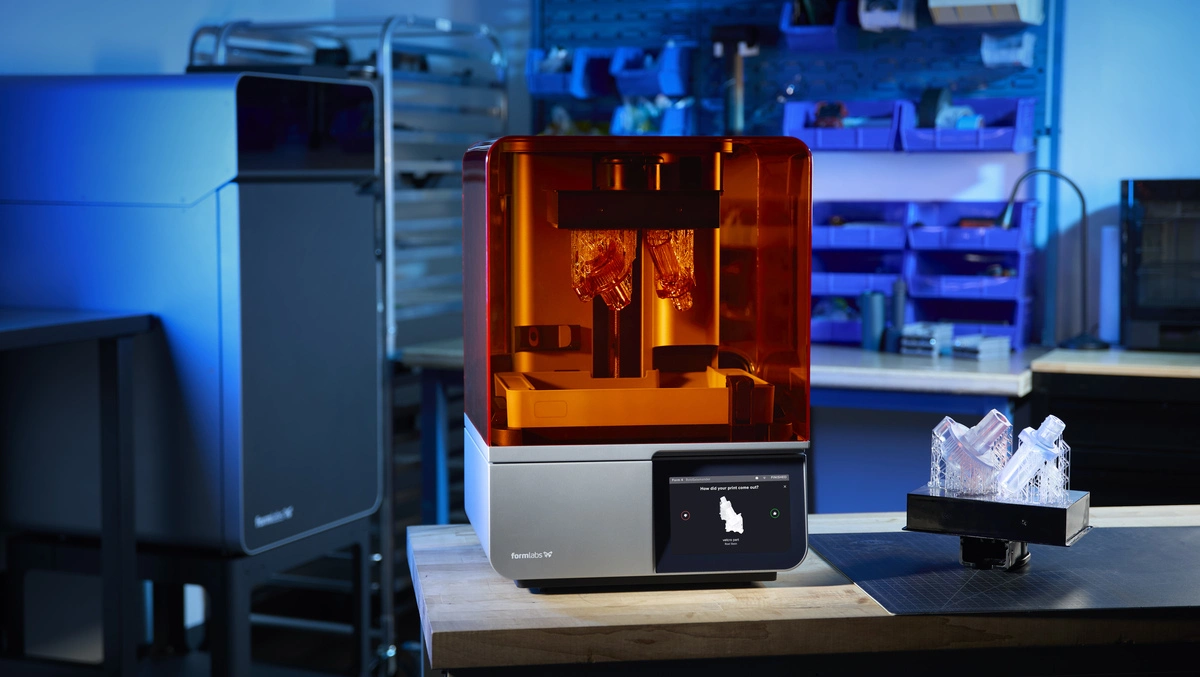

Formlabs, known for 3D printing, has announced the launch of the latest additions to its range — Form 4 and Form 4B, hailed as the most rapid and reliable 3D printers for professionals to date. The fourth-generation resin 3D printers abide by a new standard for additive manufacturing, with Formlabs introducing a new, proprietary Low Force Display (LFD) print engine, updates to their range of industry-leading resins, automated post-processing, and an improved user experience.

Particularly notable are the Form 4`s impressive print speeds, which are now five times faster, allowing product designers, engineers, manufacturers, healthcare professionals, and innovators unprecedented productivity, with the potential to take higher design risks and bring products to market more speedily.

Max Lobovsky, CEO and Co-founder, Formlabs, described the development: "Form 4 is a huge leap not only for Formlabs and our customers but also for the entire 3D printing world. More than a decade ago, Formlabs created the desktop stereolithography (SLA) 3D printer category and set a new standard for accuracy, reliability, ease of use, and affordability in 3D printing. We've built on the strength and insights gathered from more than 130,000 printers on the market and over 300 million parts printed to deliver the Form 4, our best SLA printer ever. Its reliability and new level of speed will transform how our customers develop new products."

The Form 4 goes beyond previous levels of performance, delivering extremely fast print speeds, extreme reliability, top-notch material properties, excellent print quality, and intuitive operation. Among the highlights of Form 4 are blazing fast print speeds due to masked stereolithography (mSLA) technology, completing most prints in under two hours, and small parts in only minutes. It also features an ultra-power backlight (16 mw/cm2), proprietary release texture, Light Processing Unit 4 (LPU 4), dual-layer, and a flexible film resin tank.

Mark Honschke, Additive Prototyping Lead at Microsoft, attested to the prowess of the new printer: "Form 4 is our go-to choice for projects needing tight tolerances and engineering-grade materials. It produces high-performance parts with amazingly fast print times and makes it possible for our model makers to produce multiple iterations in a 24-hour period."

Bruno Alves, Development Engineer AM/IM, Ford Motor Company, also praised the Form 4, saying, "It's speed and materials versatility enable us to create multiple prototypes and manufacturing aids every day. The printer has already changed the way we design and produce parts, helping us drive efficiency in our product development."

Apart from the new printers, Formlabs is also introducing six new resins to its leading resin library. These include four newly reformulated General Purpose Resins, a Fast Model Resin for high-speed prototypes and orthodontic model production, and a Precision Model Resin for highly accurate dental models. Additionally, Form 4 is validated to use 17+ other performance materials from Formlabs materials library, with new materials to be added regularly.