Honeywell tech to boost safety & efficiency at Eneabba refinery

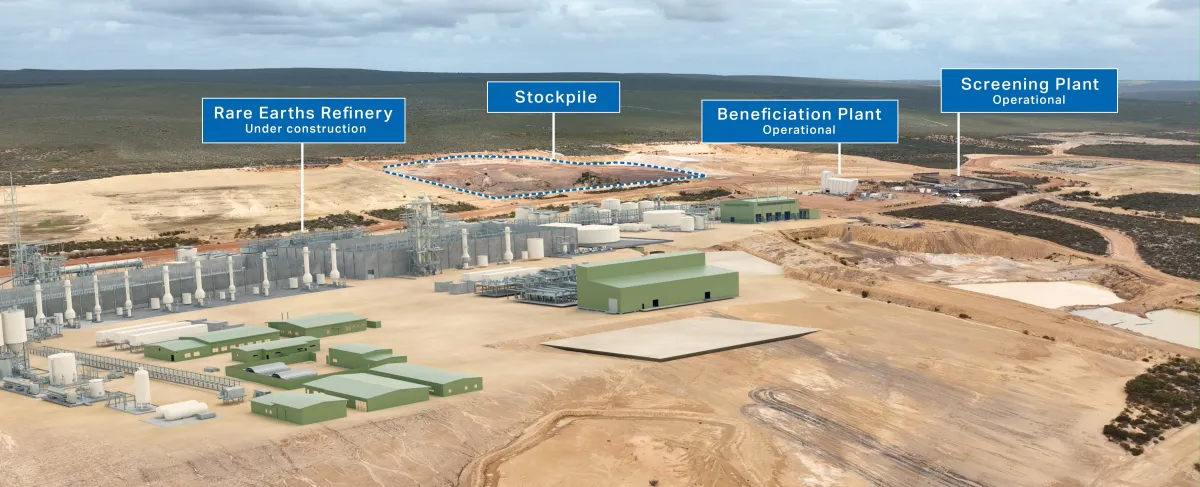

Honeywell technology will be used at Iluka Resources' Eneabba rare earths refinery in Western Australia to improve production efficiency and enhance worker safety.

The refinery, which has a capital outlay of AUD $1.7-1.8 billion, is being developed through a partnership between the Australian Government and Iluka Resources and will be the first fully integrated rare earths refinery in Australia once completed.

Honeywell will provide an Integrated Controls and Safety System (ICSS) supporting the production of rare earth oxides necessary for defence, electric vehicles, robotics, sustainable energy, and a variety of industrial and agricultural applications.

The automation and control systems will include Honeywell Experion PKS, Universal Operation Controllers (UOC) and advanced remote-control systems. These will enable Iluka to manage plant operations across the whole site with a fully integrated automation system, altering conventional approaches to plant automation projects.

The facility's safety systems from Honeywell are designed to help Iluka minimise risks of incidents, maintain high production uptime, and incorporate advanced cybersecurity functions to protect operational technology on site and in cloud-based environments.

Craig Renner, Project Director at Iluka Resources, said, "The Eneabba rare earths refinery is a significant project that underscores the importance of expanding the critical minerals sector in Australia and diversifying the rare earths supply chain. As a partner in this endeavour, Honeywell brings decades of automation domain expertise to increase productivity at the refinery while keeping our most important assets, our workers, safe."

The refinery is forecast to produce up to 6,250 tonnes per year of separated neodymium, praseodymium, dysprosium and terbium oxides. These are considered globally-significant volumes and will contribute to Australia's efforts to strengthen domestic supply chains for critical minerals used in electrification technologies.

Honeywell's systems are expected to deliver operational efficiencies through real-time data analytics, which will facilitate quicker decision-making for site operators across the Eneabba facility.

Pramesh Maheshwari, President of Honeywell Process Solutions, said, "Our partnership with Iluka demonstrates how automation is a key driver of the global energy transition supply chain. With Honeywell's extensive expertise in automation, Iluka will be equipped with the necessary tools to enhance the safety and efficiency of its operations, which are vital for supporting a more sustainable future."

The Eneabba refinery is scheduled to be commissioned in 2027, and will contribute to Australia's capacity to supply essential minerals for a range of manufacturing and energy applications.