New manufacturing lab to open at TAFE Queensland

A state-of-the-art advanced manufacturing lab is being developed by Applied Robotics for TAFE Queensland, featuring prominent technologies from Rockwell Automation. This project, valued at AUD $3 million, is part of the Queensland Government's USD $100 million Equipping TAFE for our Future initiative.

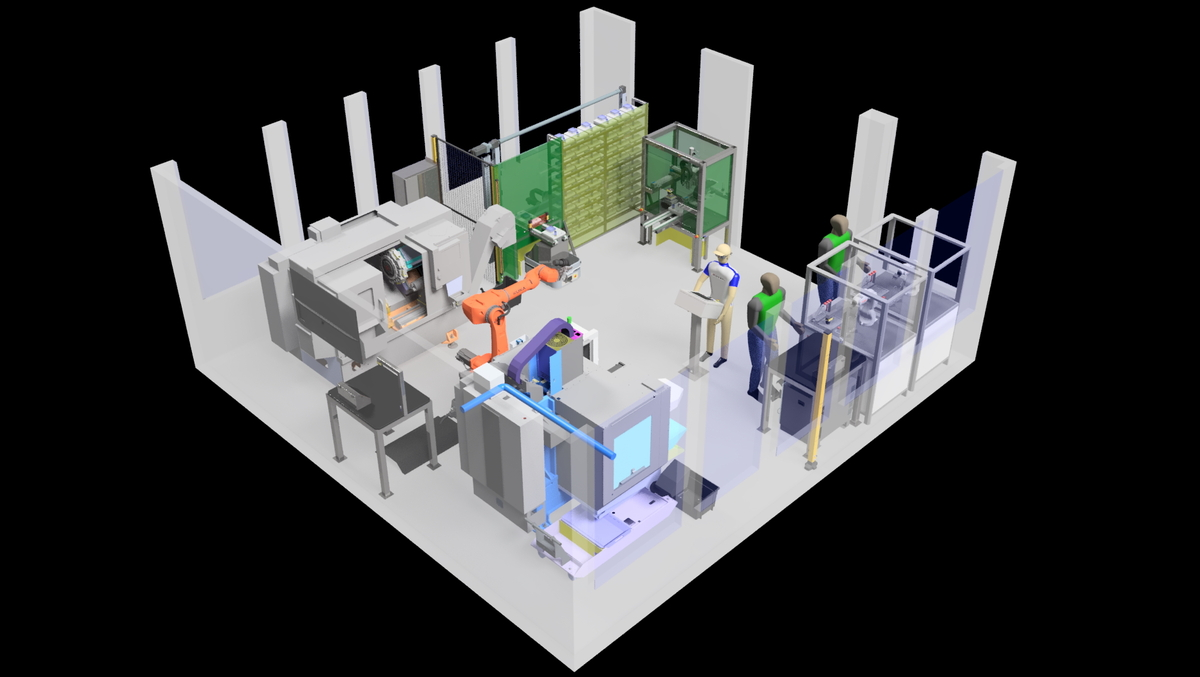

The facility, which is scheduled to be operational by February 2025, is located at TAFE Queensland's Ipswich campus. It aims to provide comprehensive training in robotics, CNC machining, machine vision and learning, and automated logistics and storage, preparing Australia's future engineers, manufacturers, and innovators.

Isaac Roach, Chief Operating Officer at Applied Robotics, expressed confidence in Rockwell Automation's role in the project. "We've had a long partnership with Rockwell, extending more than 30 years, so when we won the project to deliver this smart manufacturing lab, we knew Rockwell had the expertise and technologies to meet our needs," he said. Roach noted that Rockwell's ability to provide a range of technologies, including IoT, MES, logistics technologies, PLCs, digital twin visualisation, and AMRs, from a single supplier was unique. "Not many suppliers have all the technologies under one roof," he added.

The lab's focus on training extends to equipping trainers with necessary expertise, facilitated by Rockwell's involvement. The implementation of Plex, a Software as a Service Smart Manufacturing Platform, will connect different elements of the lab's operations. Roach highlighted the significance of this integration, stating, "A key outcome set out by the TAFE was that we needed to be able to train the trainers, so they are well-equipped to teach students in the new lab. Rockwell was instrumental in achieving this, particularly with its Plex software running the entire system with control down to the device level."

Anthony Wong, Regional Director for South Pacific at Rockwell Automation, underscored the importance of the lab for future talent. "It's vital to nurture the next generation of manufacturing talent, and advanced labs like this will help train Australia's innovators and entrepreneurs of the future," he said.

Rockwell Automation also contributed to the lab's design for an educational purpose, particularly with a twinned PLC System that allows students to programme and test skills with the flexibility of reverting to original settings if needed. This approach is further enhanced by the inclusion of Emulate3D, digital twin software for plant visualisation and testing.

Another highlight is the inclusion of Rockwell's OTTO Motors Autonomous Mobile Robots (AMRs), marking one of the first local installations following Rockwell's acquisition of Clearpath Robotics. Roach remarked on the role of AMRs, saying, "AMRs are at the forefront of industrial automation, so it was important to include them in the smart manufacturing lab. OTTO Motors AMRs are respected globally for enhancing productivity for manufacturing facilities."

With the progress on the TAFE Queensland lab, Applied Robotics is exploring further collaboration opportunities. Roach noted interest from other Australian educational institutions and stated, "People are impressed with what this industry and education partnership is set to achieve, and we've already had other educational institutions in Australia interested in a similar set up. We are excited about these possibilities, and will look to continue to expand our strong partnership with Rockwell to continue delivering for the Australian education sector."

.webp)